Feature Extraction for Synthesis and Design of Complex Material Microstructures

Collaborators: Ruijin Cang, Dr. Yang Jiao, Dr. Yongming LiuAbstract

Integrated Computational Materials Engineering (ICME) aims to develop scalable design methodologies for complex material systems by leveraging and extending knowledge from material science and design automation. The key challenges are (1) the high dimensional design representations of material structures and (2) the high computational cost for physics-based process-structure-property mappings. For (1), we develop unsupervised learning models that learn lower-dimensional feature spaces from where new designs (microstructures and topologies) can be created based on samples; for (2), we integrate deep learning and physics-based models to discover key factors (e.g., microstructure patterns) that influence properties of interest (e.g., fracture strength).

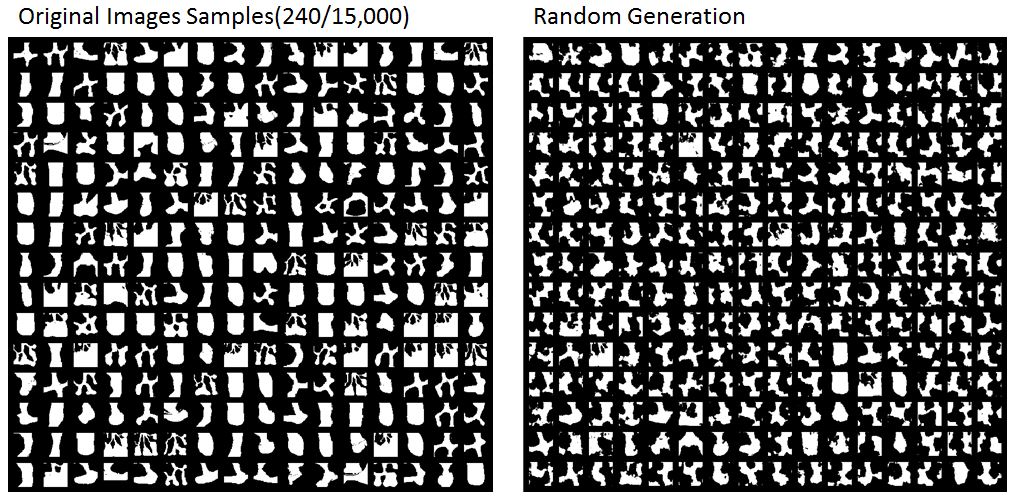

Images

(Top) Original samples from Ti-6Al-4V alloy, Pb-Sn alloy, Fontainebleau sandstone, and spherical colloids (Bottom) Random reconstructions by learning from the samples (Cang et al., 2016, 2017)

Augmented variational autoencoder for scalable topology optimization (Paper in preparation, collaboration with Engineering System Design Lab@UIUC)

Finding a low dimensional design space for accelerated material design through deep learning (Paper in preparation, source code)

Related Papers

1. Cang, R., Xu, Y., Chen, S., Liu, Y., Jiao, Y., and Ren, Y. (2017). Microstructure Representation and Reconstruction of Heterogeneous Materials via Deep Belief Network for Computational Material Design. ASME Journal of Mechanical Design. arXiv , Source Code

2. Cang, R., and Ren, Y. (2017). Scalable Microstructure Reconstruction with Multi-scale Pattern Preservation. In ASME 2017 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. American Society of Mechanical Engineers. pdf